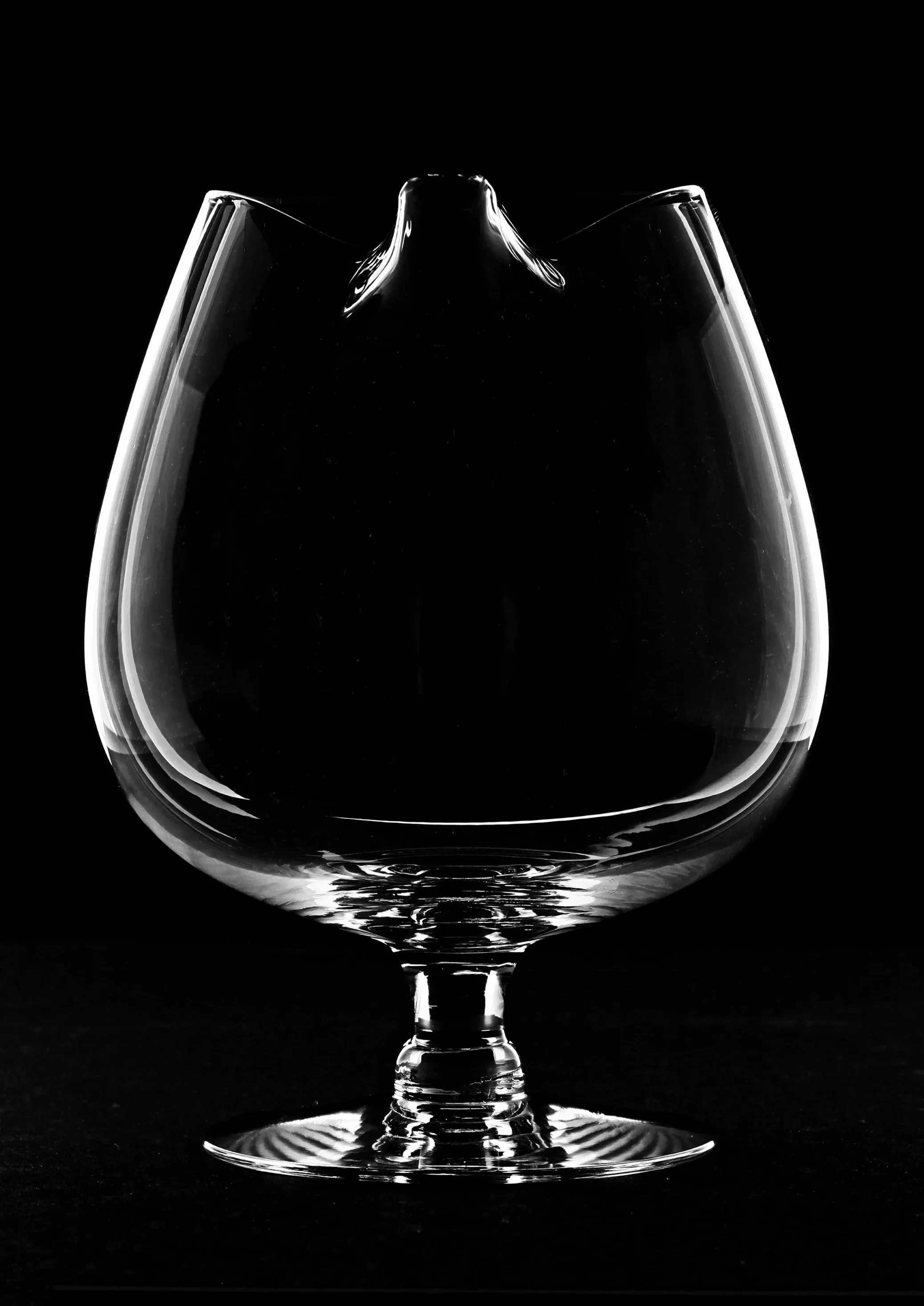

Glass Pitcher – Backlit Material & Surface Evaluation Documentation

Component: Glass pitcher

Application: Formed glass vessel (consumer product / transparent component)

Study Type: Non-destructive visual inspection (backlit photography)

Imaging Objective

Document the form, thickness variation, surface clarity, and internal material characteristics of a glass pitcher in as-received condition to support material behavior assessment, manufacturing quality evaluation, and visual engineering analysis.

Imaging Methodology

High-resolution backlit photography was performed using a controlled white softbox environment to isolate the subject and eliminate uncontrolled reflections. A black panel sized to the pitcher was positioned behind the component to define external edges and improve silhouette contrast. Two white flags were placed at approximately 45-degree angles at the front of the subject to manage specular highlights and maintain even tonal transitions.

A strobe equipped with a large softbox was positioned behind the pitcher, transmitting light through the glass to reveal internal structure, thickness variation, and edge geometry. Imaging was conducted in an as-received condition prior to cleaning or surface modification.

Observations

Overall form appears uniform with smooth curvature and consistent silhouette.

Thickness variation is visible along the rim, handle interface, and base, highlighted through controlled backlighting.

Edge definition is clean, with minor optical distortion consistent with formed glass manufacturing processes.

Internal striations and flow patterns are visible, indicative of glass forming and cooling behavior.

No visible cracks, chips, fractures, or structural discontinuities observed within the documented views.

Engineering Interpretation

Visual evidence suggests material characteristics consistent with standard formed-glass manufacturing processes rather than defect-driven anomalies. Observed thickness variation and internal flow patterns reflect normal material behavior and cooling dynamics. Backlighting effectively exposes optical density changes, supporting evaluation of material uniformity and structural consistency. No visual indicators suggest compromised functional integrity.

Use Case

Images used to support:

Non-destructive inspection of transparent components

Material behavior and thickness visualization

Manufacturing quality assessment

Engineering documentation and comparative analysis

Notes

This documentation reflects optical and surface-level visual analysis only. No dimensional measurement, stress testing, or material composition analysis was performed. No digital modifications affecting structural interpretation were applied beyond tonal normalization and exposure balancing.

Technical Spec Sheet – Back-Lit Glass Pitcher Study

Subject:

Back-lit glass pitcher — transparency, edge definition, and surface clarity study.

Camera & Support:

Camera: Canon EOS 5D Mark II

Lens: 70mm

Stabilization: Tripod

Shutter Triggering: 2–10 sec timer (to eliminate vibration)

Exposure Settings:

Shutter Speed: 4 seconds

Aperture: f/16

ISO: 100

Lighting Setup:

Primary Light: Profoto strobe, power level 1

Modifier: Large softbox (rear-positioned) for diffused backlighting

Pitcher Placement: Positioned inside a softbox to control reflections, on a black mirror for reflection.

Background: Black board placed directly behind pitcher to define edges

Fill/Reflection: White foam core board angled at 45° to bounce soft light back onto the front surface and reveal subtle glass contours

Technical Spec Sheet – Three-Light Strobe Portrait (Guitar Performance Study)

Subject:

Male guitarist — performance portrait capturing gesture, instrument detail, and expressive body language.

Camera & Support:

Camera: Canon EOS 5D Mark II

Lens: 85mm

Exposure Settings:

Shutter Speed: 1/125 sec

Aperture: f/8

ISO: 100

Lighting Setup:

Key Light (Primary):

Light: Profoto strobe

Modifier: Medium softbox

Position: 45° to subject, slightly above eye level

Fill Light (Secondary):

Light: Profoto strobe

Modifier: Large softbox or umbrella

Position: Opposite side of key, lower power

Rim / Accent Light (Third Light):

Light: Profoto strobe

Modifier: Strip softbox or bare head with grid

Position: Behind subject, angled toward shoulders and guitar neck

Objective:

To capture a dynamic performance portrait that balances expressive motion with clear detail in both the musician and the instrument. The lighting emphasizes facial expression, hand movement, and the guitar’s form while maintaining depth and separation.

Technique Notes:

This three-light configuration allows independent control of facial illumination, shadow density, and edge definition. The approach mirrors multi-source automotive lighting workflows, where primary form, secondary detail, and accent highlights are carefully shaped to communicate motion, material quality, and design intent.

Technical Spec Sheet – Experimental Back-Lit painted Wine Glass with Top Black Light

Subject:

Painted Wine Glass — transparency, rim definition, and stem clarity study with controlled edge highlights.

Camera & Support:

Camera: Canon EOS 5D Mark II

Lens: 70mm

Stabilization: Tripod

Shutter Triggering: 2–10 sec timer (to eliminate vibration)

Exposure Settings:

Shutter Speed: 4 seconds

Aperture: f/16

ISO: 100

Lighting Setup:

Primary Light: Profoto strobe, power level 1

Modifier: Large softbox positioned behind the subject for diffused backlighting

Subject Placement: Wine glass positioned inside the softbox to fully control reflections

Background: Black board placed directly behind the glass to define outer edges and stem separation

Front Fill / Reflection Control

Top Light Control

Objective:

To capture clean edge highlights, crisp rim definition, and uniform transparency while maintaining controlled contrast throughout the bowl and stem. The addition of the top black flag creates intentional rim separation and enhances the dimensional read of the glass form.

Technique Notes:

This setup combines rear diffusion, reflective fill, and strategic negative fill to sculpt transparent material. The top black flag introduces a controlled dark line at the rim—an essential technique for defining form in glass and similarly reflective automotive materials such as lenses, touchscreens, and polished trim. Long exposure and low ISO ensure maximum clarity, tonal consistency, and minimal noise.